The future of sustainable aluminium in Europe

There was a time when aluminium was regarded as more prestigious than gold or silver. In the rise of aluminium manufacturing of the 19th century, this shiny metal was so complicated to extract from ore, that it was scarce as diamonds.

The French emperor Napoleon III had been a great supporter of research back in the early days of aluminium manufacturing, though not from mere scientific curiosity. He was hoping to equip his army with lightweight but resilient shields made from this new metal. However, refining costs stayed too high and the plan failed; thus Napolean pressed his reserves into cutlery. It was rumoured he ate off of the aluminium plates while his guests had to accept ordinary gold plates.

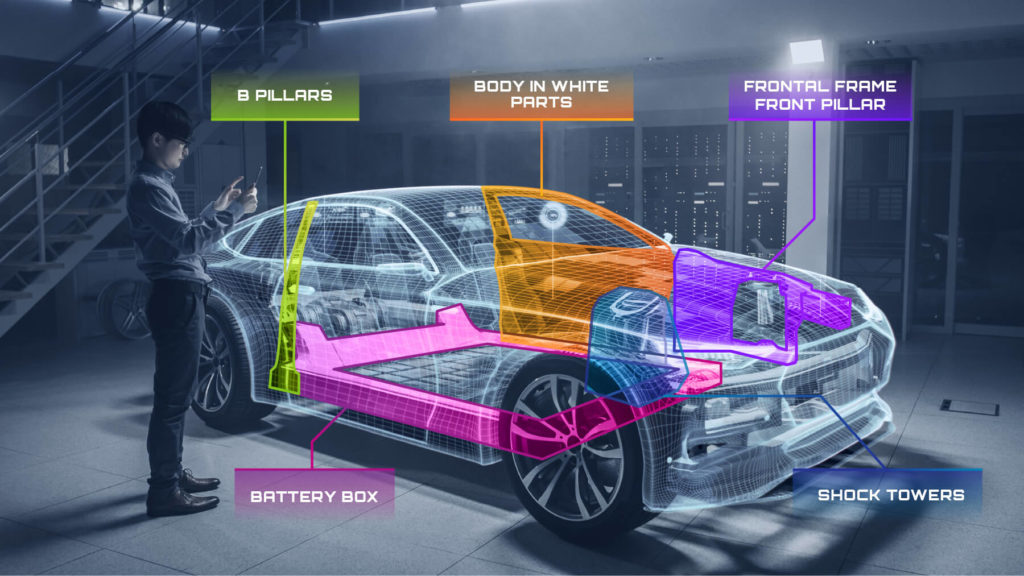

Due to technological advances, things have changed around aluminium through the centuries and it has become one of the most widespread metals for its machinability, electrical conductivity, and 100% recyclability. Today we can find it everywhere, from cellphones and kitchen utensils to spaceships and rockets. In the automotive sector, aluminium is the fastest-growing material, and the Horizon 2020 project SALEMA (Substitution of critical raw materials on aluminium alloys for electric vehicles) funded by the EU is here to make it more sustainable as well.

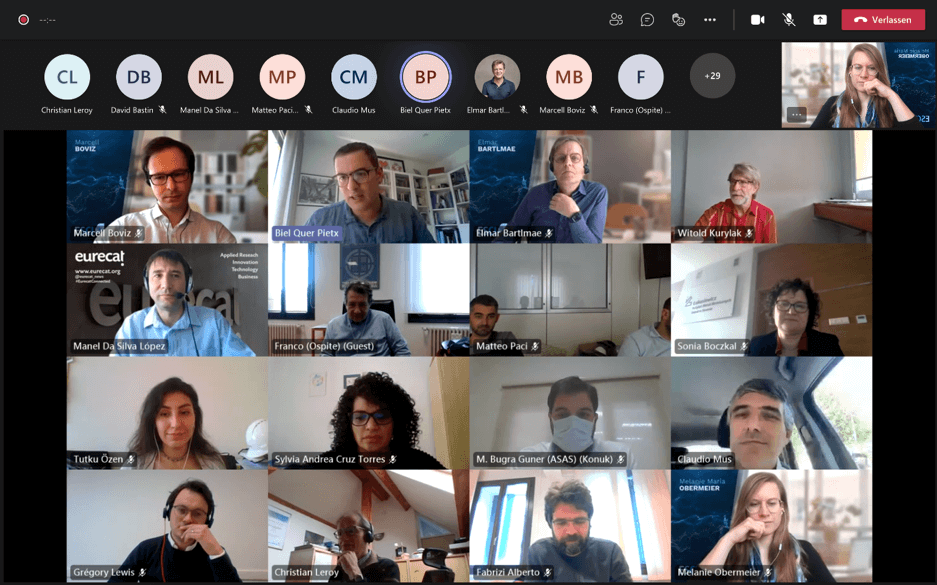

The project includes 16 partners from industry-leading companies, research institutes and not-for-profit organisations in six EU countries. According to Hannah Arpke the project coordinator from EURECAT „the project goal is twofold: firstly we aim to develop aluminium grades with high amount of recycled material” by validating and implementing a circular economy model, while „the second is to demonstrate the feasibility of iron to majorly substitute the most commonly used critical raw materials in aluminium alloys.”

The result of SALEMA will be new tailored-made aluminium alloys with a higher amount of recycled material, primarily designed for electric vehicle manufacturers. Perhaps Napoleon couldn’t invade his enemies with aluminium shields, but now aluminium is here to become the most common metal used in automobiles in a new greener way!