Driving sustainable aluminium

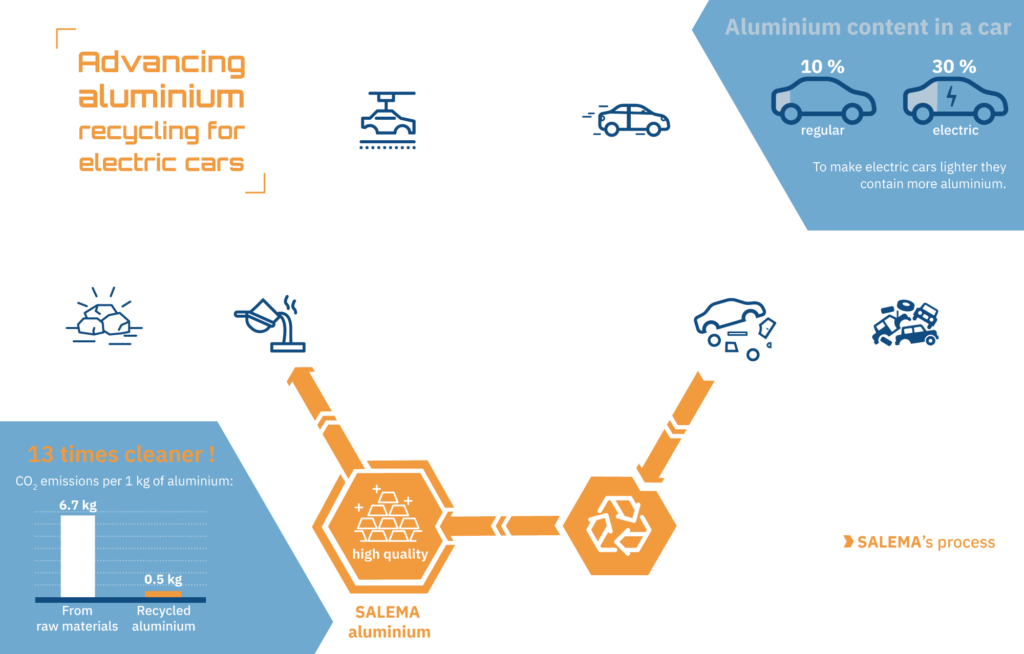

The SALEMA project has combined the strategies of decreasing the use of critical raw materials and creating a sustainable economy in the aluminium manufacturing industry of Europe. The electric automotive sector needs high-performance, sustainable aluminium sources, which is only possible by generating a new aluminium ecosystem.

Circular economy model

16 Partners from six countries united to create brand new, sustainable and high-performance aluminium alloys, and demonstrate their suitability in automotive applications.

SALEMA developed and put into practice a circular economy model that integrates scrap aluminium materials into the process of manufacturing aluminium car parts. This circular economy will lead to a more sustainable industry and less dependence on imports from outside the EU.

Solutions developed in the project

SALEMA is demonstrating the new circular economy model on 5 car parts in 4 pilots in Europe.

Follow our journey

Driving sustainable aluminium: SALEMA alloy design and recycling for future mobility

Learn more

Ensuring supply and sustainability of critical raw materials

Learn more

Using specialist knowledge to produce SALEMA alloys

Learn more

Recycling aluminium: the route to lighter cars and decarbonising materials

Learn more

Collaborating for circularity in the aluminium value chain

Learn more

SALEMA presents results at E-TECH Europe 2024

Learn more

Filling a gap between alloy development and industry needs

Learn more

Developing a multi-sensor robotic scrap sorting system

Learn more

Increasing recycled content while keeping performance

Learn more

SALEMA presents near-final results to stakeholders

Learn more