Short interview: Andrea Bongiovanni

Curiosity about how things are made and how they work is what led materials engineer Andrea Bongiovanni to a PhD research role with SALEMA partner Centro Ricerche Fiat, and to work on two of our five demonstrator car parts in collaboration with Endurance Overseas.

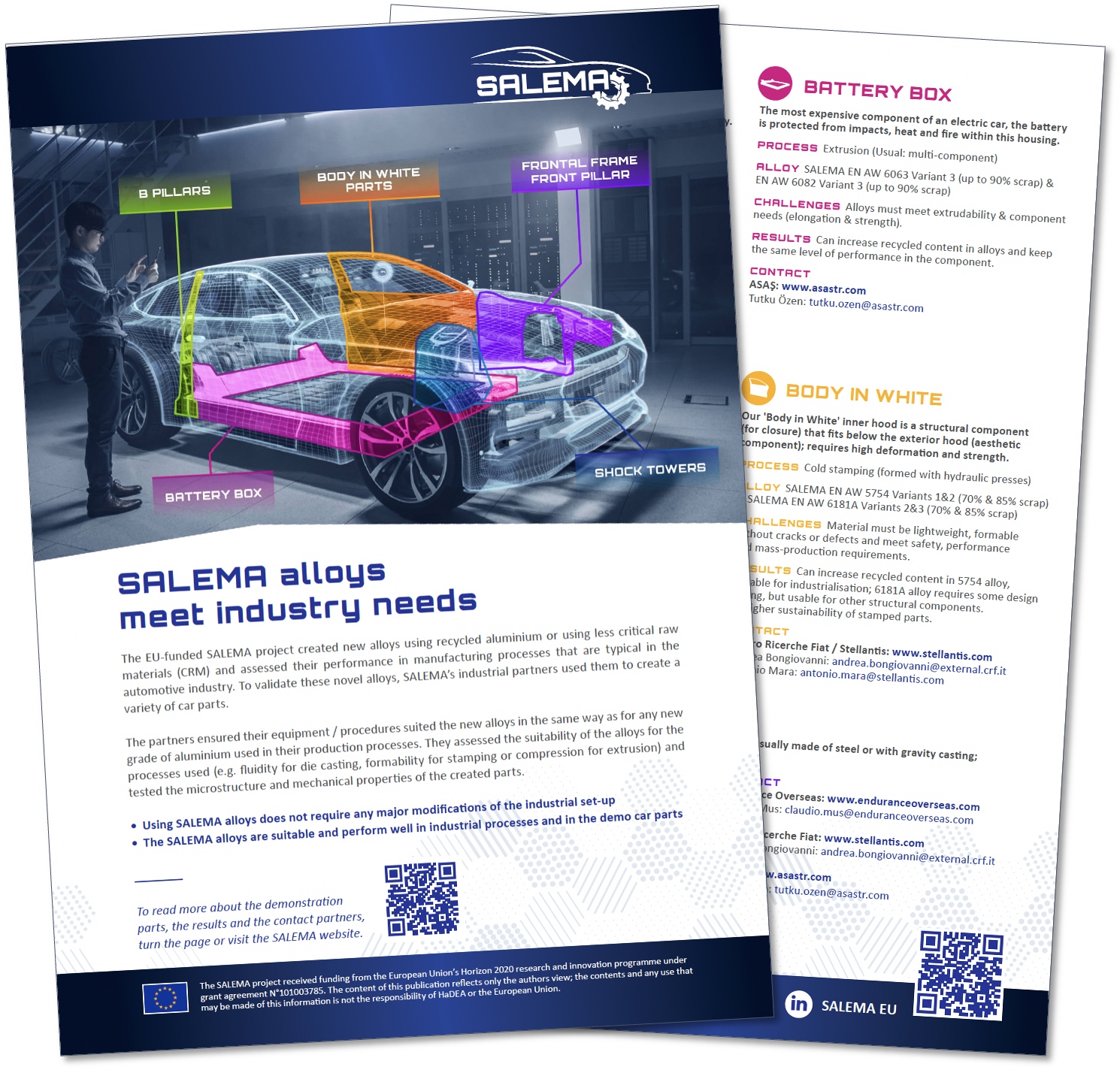

As industry faces the need to decrease its carbon footprint and increase the sustainability of the metal alloys used in vehicles, Andrea’s PhD focused on assessing the metallurgical, mechanical and functional properties of SALEMA’s new aluminium alloys, which contain more recycled content or lower amounts of critical raw materials (CRM). In particular he studied the alloys created for use in industrial high-pressure die casting.

We asked Andrea a few questions…

How will SALEMA help to improve future cars?

The SALEMA project is an opportunity because it’s the trend that automotive is facing towards more sustainable aluminium alloys, especially for structural parts, and so increasing the recycle and re-use of what we already are using, so what we already imported as critical raw material, is the very key to solve this problem.

How has your organisation contributed to SALEMA?

We provided the design, the original design of the component, to create the SALEMA demonstrator. And so we also provided help in developing it with its mechanical properties, when it is needed and where it is needed for the final use.

We have got very promising results and very good results in respect to what we asked, and so it’s a very promising alloy and a promising component for us.

See Andrea in SALEMA’s final event

What makes SALEMA unique?

When you design a component and you think about the material, maybe sometimes you lose focus on what is the industrial scale and what are the industrial issues or dimensions. And so when you do have that in mind, also, you can think about the design better fitting the material and also the final properties that are the outcome.

I think that the results, the outcomes of this project are very interesting because it goes to fill a sort of gap that there was between the development of these recycled alloys with what the industry asked. So high-recycled alloys, end-of-life scrap recycled alloys with high mechanical properties, but not from just an academic point of view, but a real industry level.

Would you drive an electric car made with SALEMA alloys?

Yes sure! More aluminium is lighter and also more sustainable, and so I think that it would be pleasant to drive that, with that in mind.