Solutions

Key technologies

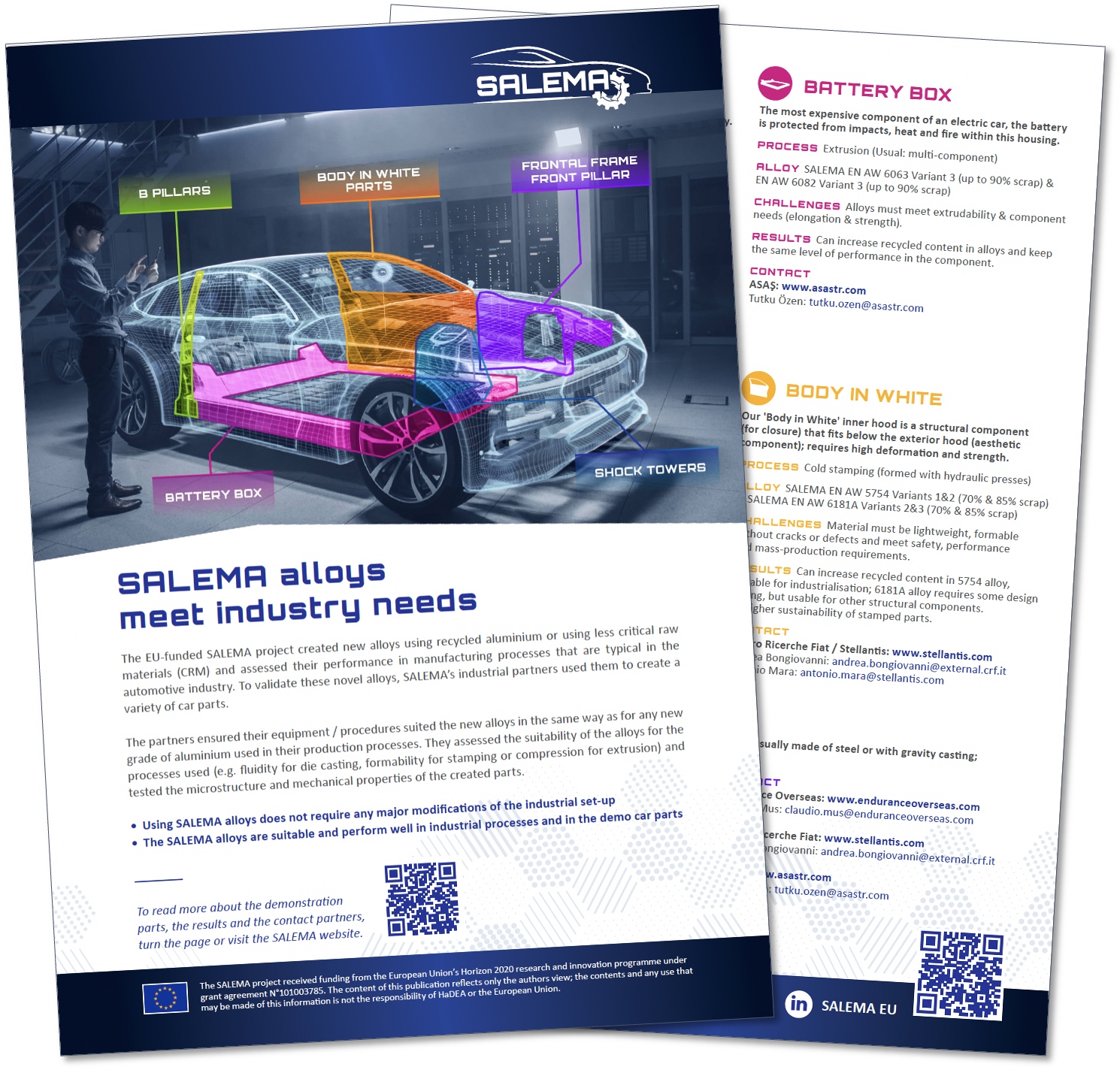

SALEMA set up four pilots by adapting existing industrial facilities. To validate the novel low critical raw material aluminium alloys, the existing facilities of the industrial transformation partners were adapted to the requirements of the newly developed alloys. The adaptation of the equipment was equivalent to the usual implementation procedure of a new aluminium grade, involving no major modifications of the setup. Read more about the four pilots and demonstrators below!

Demonstrators

Overall 5 case studies were used to assess the performance of the new SALEMA alloys in the most relevant processing routes for the automotive industry. These demonstrators were selected to cover a wide range of potential applications of the newly developed alloys, and investigated the most common and future promising transforming processes to speed up market up-take.

High-Pressure Die Casting (HPDC)

In this manufacturing technique, molten aluminium is injected under high pressure into a die. After the metal has solidified, the die is opened and the car part released.

To validate the developed alloys, the SALEMA partners produced shock towers and frontal frame components using high-pressure die casting.

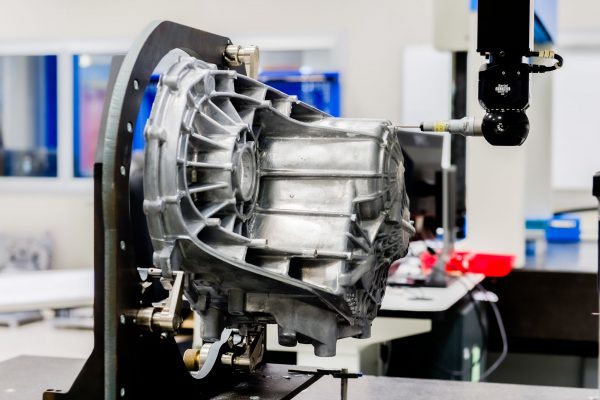

Shock Tower

It’s a structural component of the car, responsible for stability, driving comfort and safety in case of a crash. It connects the shock absorber with the front body and disperses all forces taken up by the shock absorber. Shock towers are commonly formed using sheet metal fabrication techniques.

Using the SALEMA alloys, FAGOR produced shock towers from a commercial FORD model using high-pressure die casting.

Frontal Frame

The frontal frame of a car is commonly composed of several assembled parts, some of them made of steel or thick gravity casting. There is a huge potential in weight reduction by redesigning and adapting these components so they can be produced using a combination of high-pressure die casting and extrusion processes.

SALEMA partners ENDURANCE, CRF and ASAS explored this possibility by designing and producing a new demonstrator component based on these two processing technologies with the newly developed alloys. They manufactured a novel front-pillar for a future Fiat model. After its successful validation, it can be used for the development of variants to be introduced in new vehicles design.

Stamping

The stamping process reshapes aluminium sheets using moulds. Placed in between the parts of the mould, the metal is compressed by either hydraulic or mechanical presses. The difference in cold and hot stamping lies in the temperature applied during the deformation process.

Hot and cold stamping were employed to manufacture B-pillar and Body in White parts.

Body in white

Cold Stamping

Body in White describes the fully assembled car body before painting and installation of the engine, electronics, glass, seats, etc. There is a strong interest in the automotive industry for new lightweight materials which meet the safety, performance and mass production requirements of the Body in White.

To test the SALEMA alloys for these criteria, CRF produced a Body in White component of commercial geometry using cold stamping – an inner hood.

B-Pillar

Hot Stamping

The B-pillar is typically a closed metal structure welded from the car’s floor pan at the bottom to the roof panel at the top. It is a critical component of the car’s safety cage – the rigid compartment that surrounds and protects the passengers. In the event of a side impact or rollover, the B-pillar needs to dissipate the energy of the impact.

To test the formability and performance of the SALEMA alloys, GESTAMP produced the foot of a B-pillar using hot stamping.

Extrusion

The partners shaped the SALEMA alloys into a battery box and components for a novel frontal-frame using extrusion.

Battery Box

The battery is the heart and the most expensive component of an electric car. It is housed in a protective metal box designed to make this core element crash-proof.

ASAS manufactured a battery box housing using extrusion, in collaboration with the MARBEL project.