Project

ABOUT:

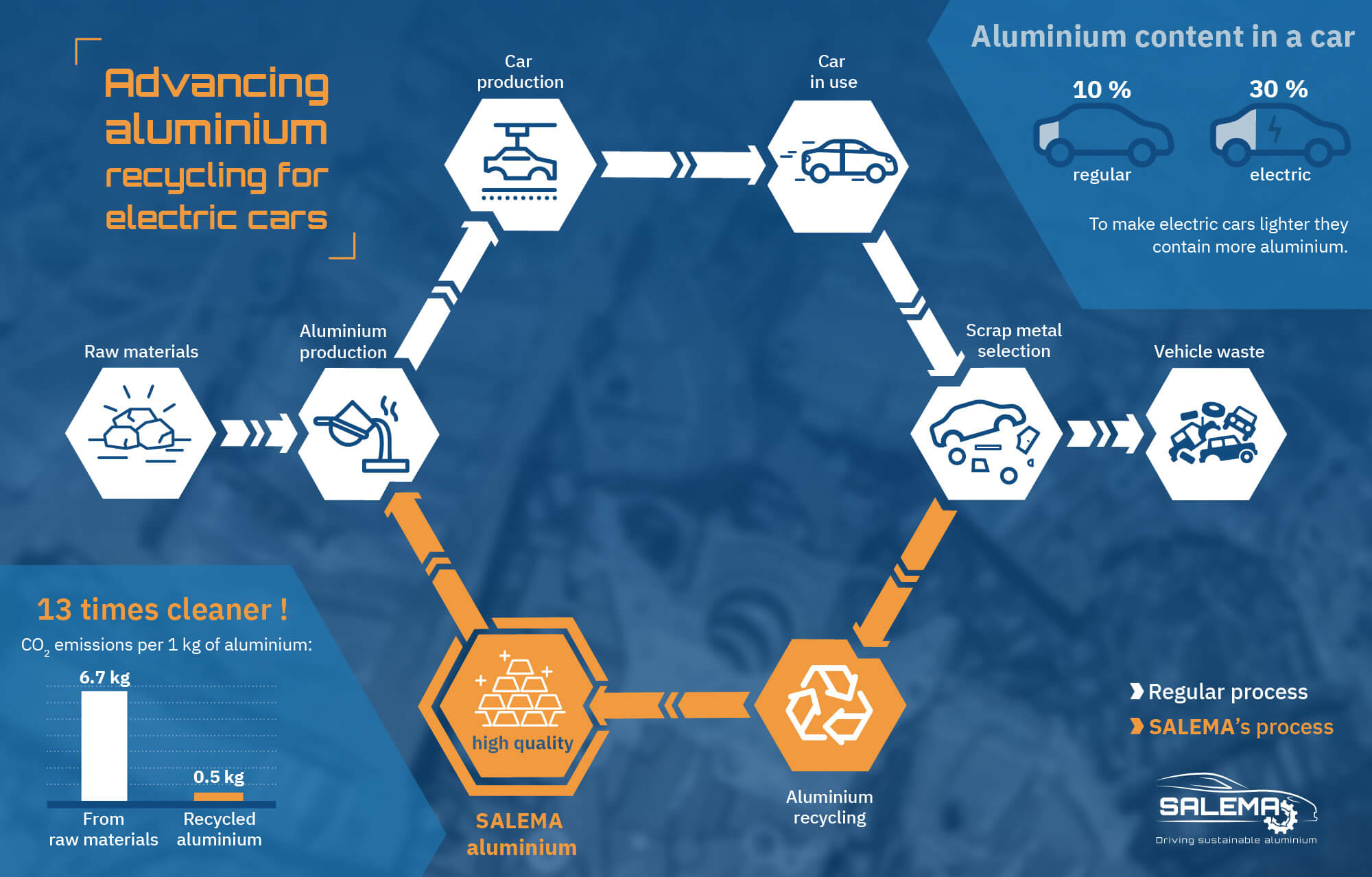

The automotive industry is facing multiple challenges to meet the goals of the European Green Deal. It needs to produce new, high-performance but lightweight materials and decrease the dependencies on imported raw materials while creating a sustainable economy for the future. How do you solve this puzzle? SALEMA partners see the solution in aluminium. This lightweight, cost-effective and fully recyclable metal can meet the highest technical requirements and is ready for mass production.

Aluminium is not a new solution in cars. Around 15% of all parts are made from aluminium in large scale production cars, while this number is higher than 50% in the case of electric vehicles. And the demand for aluminium for automotive use is growing every year. So the European automotive sector needs reliable aluminium sources, that are not dependent on foreign critical raw material imports.

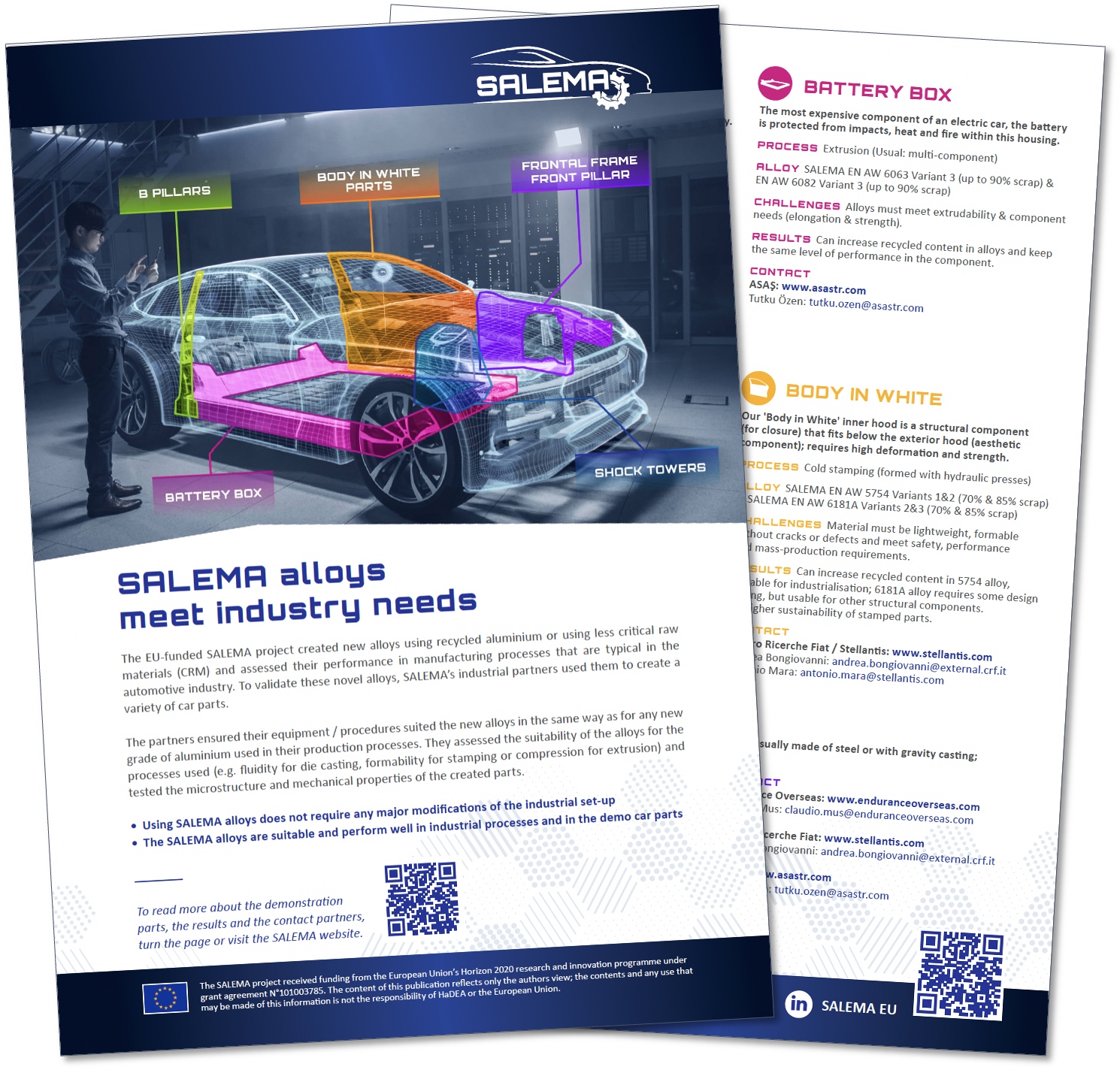

The SALEMA project designed and produced novel aluminium alloys with minimal critical raw material content (silicon and magnesium), or by integrating scrap metal recycling. The suitability and performance of these new aluminium alloys was demonstrated through four pilot actions and five demonstrators. The integration of scrap metal recycling is essential to create a sustainable circular economy and will serve as a reliable source for high-quality alloys in the future.

16 partners from six European countries joined forces because, we believe, driving towards a green automotive industry starts with lightweight cars made of aluminium.

GOALS and RESULTS:

SALEMA implemented and validated a fully circular economy model:

SALEMA combined expertise from across the aluminium value chain:

SALEMA’s approach and achievements support Europe’s goals:

Alloy design

SALEMA devised a methodology and designed 31 alloy 'recipes':

SALEMA tested the new high-recycled / low CRM alloys:

SALEMA selected 10 new alloys as suitable for:

SALEMA’s design methodology benefits future research and learning:

Improved recycling

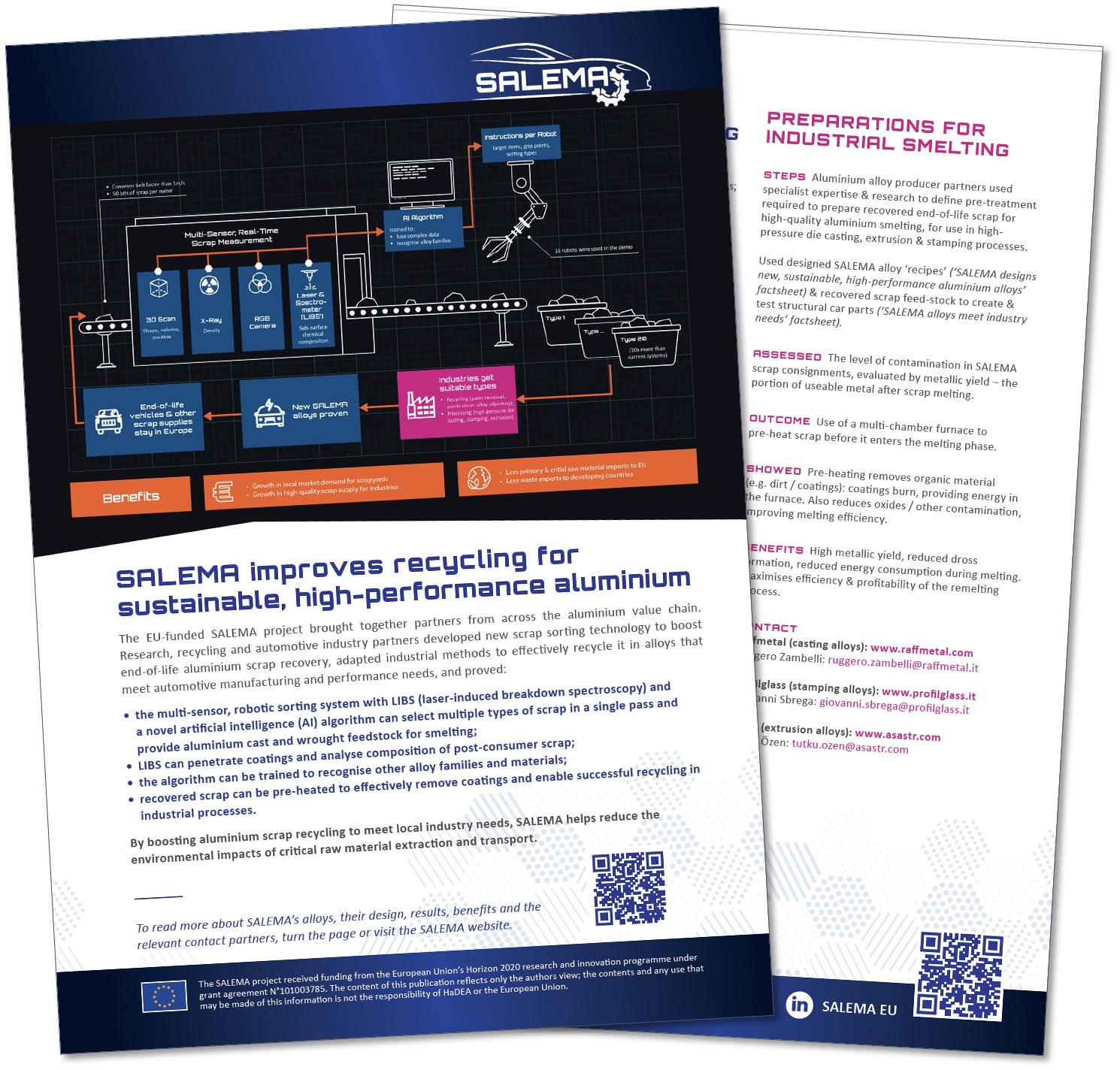

SALEMA developed sorting technology to boost end-of-life aluminium scrap recovery:

SALEMA extracted 4 qualities of aluminium scrap from end-of-life-vehicle shredded scrap:

SALEMA proved successful real-time separation of targeted aluminium alloys in scrap:

SALEMA defined pre-smelting treatment of end-of-life scrap for high-quality aluminium:

Demonstrators

SALEMA showed can increase recycled content in alloys and keep high-level performance of components:

Follow our journey

Driving sustainable aluminium: SALEMA alloy design and recycling for future mobility

Learn more

Ensuring supply and sustainability of critical raw materials

Learn more

Using specialist knowledge to produce SALEMA alloys

Learn more

Recycling aluminium: the route to lighter cars and decarbonising materials

Learn more

Collaborating for circularity in the aluminium value chain

Learn more

SALEMA presents results at E-TECH Europe 2024

Learn more

Filling a gap between alloy development and industry needs

Learn more

Developing a multi-sensor robotic scrap sorting system

Learn more

Increasing recycled content while keeping performance

Learn more

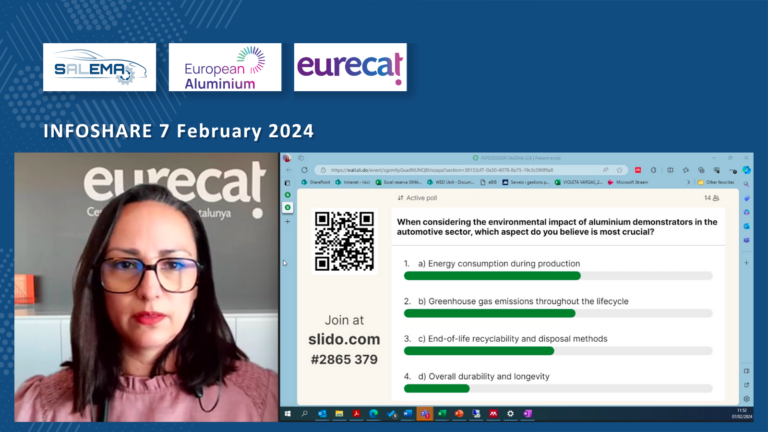

SALEMA presents near-final results to stakeholders

Learn more