In a quest for more sustainable, lightweight, and crash-resistant vehicles, European aluminium and automotive industries are taking significant steps forward. In the webinar ‘The Circular Metal for Future Mobility’, held on 6 October 2023 as part of the EU-funded SALEMA project, experts showcased ground-breaking research developments in aluminium and advanced materials.

With a focus on developing high-performance alloys, reducing dependence on primary-source critical raw materials (CRMs), and enhancing the recycling process, the webinar showed how the future of mobility can be greener and more sustainable.

The need is growing for efficient scrap control and sorting processes and for the production of improved alloys from end-of-life aluminium parts. In July this year, aluminium was included in the European Union’s updated Critical Raw Materials Act (CRMA), which sets a regulatory framework for projects, a mechanism for monitoring supply chains, and measures for mitigating supply risks. Strengthening the circularity of CRM supply chains within the EU is one core objective. In recognition of this need, and to share relevant advances, the Innovation Hub of European Aluminium organised the half-day webinar within the framework of the SALEMA project.

Christian Leroy, Director of Innovation at European Aluminium, welcomed more than 60 participants representing relevant industrial, academic and technical fields. The event brought together experts from SALEMA and three other innovative EU-funded projects as well as from the aluminium and magnesium industries. “This webinar highlights the power of collaboration in driving a sustainable future,” Christian said.

In this spirit of collaboration, Martin Tauber, who is the European Representative of the International Magnesium Association (IMA), was invited to give the opening presentation, focusing on challenges and opportunities in magnesium material flows. Introducing IMA, which represents the whole magnesium value chain, he noted: “When we first heard about the SALEMA project, we saw that one of its main objectives is to reduce the use of silicon and magnesium, which of course alerted us. We have learned, and I think we agree, that we can look for a beneficial coexistence. We have to decarbonise our value chain and our contribution to one of our biggest markets, which is the aluminium alloying industry.”

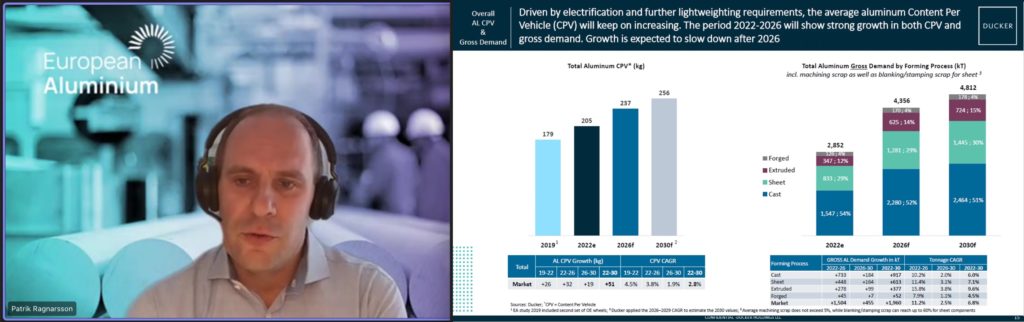

Representing the European aluminium industry’s value chain and promoting the use of aluminium as key enabler of sustainability is within the remit of European Aluminium. Patrik Ragnarsson, Director of Mobility and Strategic Projects at European Aluminium, presented the latest insights in the use of aluminium in European cars, emphasising a growing demand. “The gross aluminium demand is projected to grow by almost 2 million tons between now and 2030,” he said. “That’s a big change that the industry needs to be prepared for. And hopefully, most of this will come from European production, which is more sustainable than importing from other regions.”

Projects paving the way for greener vehicles and circular economy

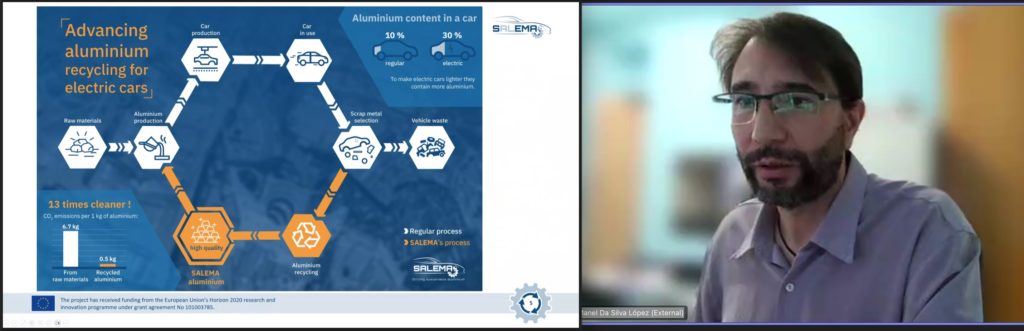

To meet the growing demands of Europe’s automotive industry, as well as those of the CRMA, European production of aluminium must minimise the use of primary-source critical raw materials while maximising scrap metal recycling. Doing this and still achieving the creation of new high-performance and lightweight metals is “quite challenging”, according to Manel da Silva López. He is Head of the Light Alloys Research Line in the Unit of Metallic and Ceramic Materials of Eurecat Technology Centre of Catalonia, and also the SALEMA project’s technical coordinator. Delivering an overview of activities and achievements, he explained that “SALEMA is developing a non-CRM dependent aluminium ecosystem by substituting the elements that are considered critical raw materials or decreasing their amount in aluminium alloys, and by harvesting these CRM elements from the scrap already in Europe.”

SALEMA’s work is already providing benefits to other projects, including Flexcrash, which is developing flexible, hybrid manufacturing of green aluminium alloy structures, with the objectives to reduce weight, increase safety and optimise crash performance of vehicles. “In Flexcrash, we are developing new aluminium powders with a high amount of recycled aluminium and a low content of critical raw materials, using part of the knowledge developed in the SALEMA project,” said Sergi Parareda Oriol, a researcher with Eurecat, who co-presented with Andoni Agirre Mentxaka of Gestamp.

Reducing weight is also a goal of the Fatigue4Light project, which is developing new tests and simulation methods to estimate the fatigue life of vehicle chassis components and select optimal materials. Lucia Barbu, Assistant Research Professor at CIMNE, the International Centre for Numerical Methods in Engineering, explained how the team studied the mechanical and environmental performance of different types of steel, aluminium and various hybrid materials. “I would say a hybrid component that involves aluminium was best in terms of weight saving. We managed to reduce the weight of the component by about 40%,” she said.

Optimising automotive component design and manufacturing processes is what the FLAMINGo project focuses on. It is working with aluminium alloys with nanoparticles with higher strength and stifness. “FLAMINGo aims to provide the automotive industry with a wider portfolio of sustainable materials,” said project representative Alvise Bianchin of MBN nanomaterialia in his presentation. “By using nanoparticles, we can enhance the strength of alloys, reducing the use of other critical raw materials.”

Take-home messages

The webinar moderators provided a concise summary of the event’s key takeaways.

Philippe Meyer, Senior Vice President and Chief Technology Officer of Novelis, highlighted the dynamism, drive to decarbonisation and ongoing competition in the aluminium and magnesium industries. He approved of SALEMA’s holistic approach, which comprises the whole value chain, saying it is “a good model to copy paste”.

Carla Barbatti, Research and Development Centre Manager for Constellium Technology Centre (C-TEC) said there’s clearly a need to develop fast tests for evaluating materials and vehicle components; different metallurgical concepts to improve strength and make aluminium attractive for automotive structures; and technologies and processes that will support the upscaling and uptake of new solutions. “We’re trying to really push the envelope in terms of design and solutions.”

The circular metal approach presented at the webinar highlights the growing commitment to sustainable practices, heralding a new era of advanced materials and eco-conscious transportation.

Further information

The presenters’ slides are available to download from the links below:

- Christian Leroy & Francesca Cavezza, European Aluminium: ‘Introduction‘ (video starts 00:00:19);

- Martin Tauber, International Magnesium Association: ‘Primary & secondary magnesium material flows – challenges and opportunities’ (video starts 00:18:14);

- Patrik Ragnarsson, European Aluminium: ‘Latest insights: aluminium content in European cars’ (video starts 00:49:33);

- Manel da Silva López, Eurecat: ‘SALEMA: New aluminium alloys for a circular electric mobility’ (video starts 01:19:30);

- Lucia Barbu, CIMNE: ‘Aluminium innovation for EV chassis components: hybrid solutions developed in the Fatigue4Light project’ 01:51:20);

- Alvise Bianchin, MBN: ‘FLAMINGo: circularity, feasibility and effects of nanoparticle inclusion in aluminium alloys’ (video starts 02:15:04);

- Sergi Parareda Oriol, Eurecat & Andoni Agirre Mentxaka, Gestamp: ‘Flexcrash: new generation of crash-tolerant structures’ (video starts 02:47:58);

- Philippe Meyer, Novelis & Carla Barbatti, Constellium: Conclusions (video starts 03:15:51).

The agenda and speaker biographies are available via our event announcement page.

See the full webinar video below.